PMS Manufactured Products, Inc. knows that the lead times for the development of products is ever shortening, and that the R&D engineers need a quick turn on the prototype that will confirm or deny the feasibility of your product.

Whether your company is in its entrepreneurial stage with a great concept but no machining know-how, or a multi million dollar enterprise with an overflowing model shop, PMS Manufacturing has a quick-turn prototyping role that will support your needs.

We help owners of smaller businesses decide what materials to use, how to form them, and how to design a prototype that will perform to function. Your engineers will know our people personally, having developed respectful relationships over the years as we provide them with engineering resources and prototyping services on an as-needed basis.

Solutions

These services contribute to PMS Manufacturing’s quick-turn sheetmetal prototyping operations:

- Experienced precision sheetmetal staff

- Wysong Precision sheet metal shear

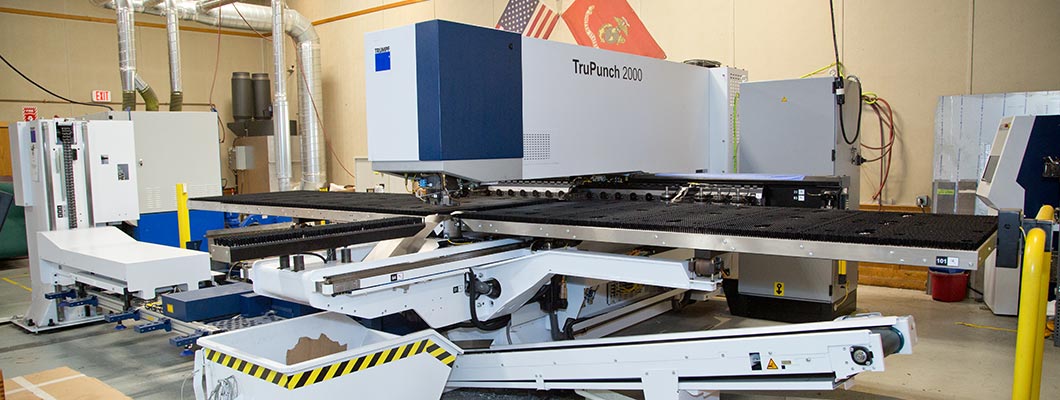

- Two Trumpf (Trumatic 120, and Trumatic 2000) Precision sheet metal punches

- A vast assortment of standard and custom tooling for prototypes and production

- Seven precision sheet metal press brakes

- Precision sheet metal welding

- Expertise with prototypes and short-run production

- Exemplary quality control and inspection facilities

- Assembly completed as necessary

PMS Manufacturing’s sheet metal reverse engineering capabilities allow designers to use input from physical components at every stage of the prototype/design through the manufacturing process. This approach not only allows for accurate design representation and rapid comparisons of physical design, but also bridges the physical to digital environments.

Geometric representation can be created in a fraction of the time of conventional CAD systems.

PMS Manufacturing’s sheet metal reverse engineering allows us to take physical parts with no CAD schematics or drawings to be brought into our CAD/CAM system for subsequent design, analysis, projection, cost analysis and manufacturing.. This is critically important, particularly when processing dozens or perhaps hundreds of parts.

PMS Manufacturing’s sheet metal reverse engineering allows us to take physical parts with no CAD schematics or drawings to be brought into our CAD/CAM system for subsequent design, analysis, projection, cost analysis and manufacturing.. This is critically important, particularly when processing dozens or perhaps hundreds of parts.